Apr 15, 2025

New Aeroderivative Turbines Add 500 Megawatts to Grid

A fleet of jet engines is whirring to life in Humphreys County, Tennessee, as the Tennessee Valley Authority brings a major power generation project online.

The elite aeroderivative gas turbines at Johnsonville Combustion Turbine Plant, west of Nashville, add more than 500 megawatts to TVA’s grid, which provides electricity to more than 10 million people across seven states.

Just like the aerospace engines they evolved from, these new turbines are designed to ramp up and down quickly, Justin McBath, senior project manager, said.

“They have a fast-start option,” McBath said. “You can go from a cold engine to full power in five minutes, generating 50 megawatts per unit – and these actually will generate up to around 57 to 59 megawatts under the right conditions.”

Also, there are no start restrictions. After being shut off, the aeroderivative turbines can restart without a waiting period.

These features make the new units highly flexible – ideal for meeting daily and seasonal peaks in electricity demand.

“These aeroderivatives represent that next class of modernization in our gas turbine fleet,” Eric Grau, vice president of gas operations, said.

“This project helps to support the continued growth and demand for electricity in the Valley by adding new generators on the system,” Grau said. “And the added benefit of these generators in particular is to provide additional reliability.”

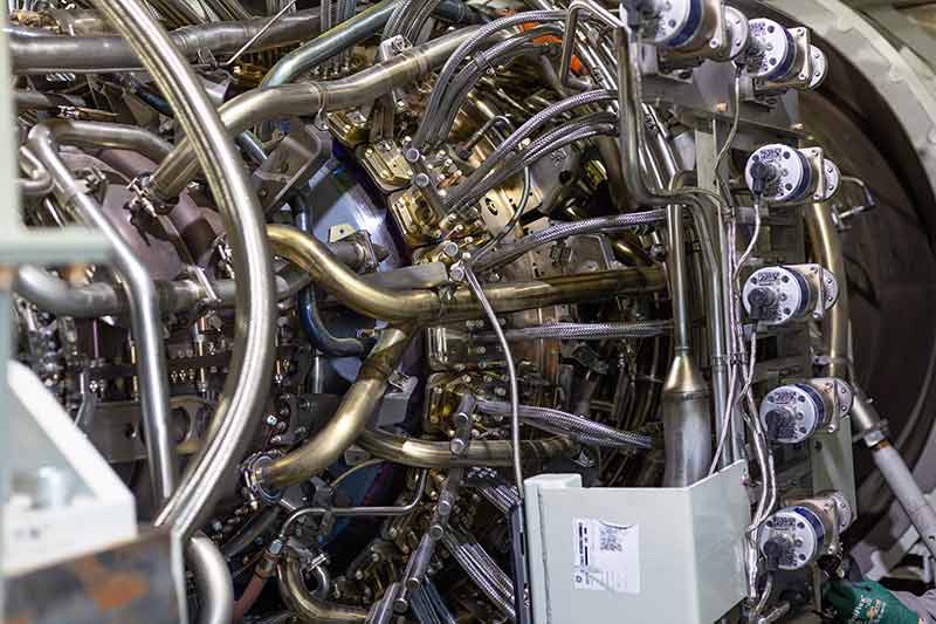

The new aeroderivative turbines at Johnsonville Combustion Turbine Plant in Humphreys County, Tennessee, add more than 500 megawatts to TVA’s grid.

Flexibility and Reliability

Along with adding megawatts, Johnsonville’s 10 aeroderivative turbines will contribute important features to TVA’s power system.

They can operate in a spinning mode without generating power, which supports stable voltage on the grid.

They can also be used to balance out fluctuations in solar generation.

And the aero units can be started with an on-site diesel generator – a boon to the entire region if a storm were to disrupt power.

“Essentially, you’ll have a power island here,” McBath said. “Then we can use that to dispatch back out to the greater grid to restore power.”

The Johnsonville aeroderivative turbines are the first of their kind for TVA, but they won’t be the last.

Construction is already underway on 16 aeros at TVA’s 1,500-megawatt energy complex on the site of Kingston Fossil Plant in Roane County, Tennessee.

The aeros fill a key niche in TVA’s balanced portfolio of affordable, reliable, resilient and increasingly sustainable power, Jamie Cook, general manager of operations projects, said.

“We have found that technologies like the aeroderivative units at Johnsonville have proven to be very functional assets that help us to meet demand, as well as reliability needs and flexibility needs,” Cook said.

“We’re really excited to see how much value these units bring to the fleet.”

‘Gorgeous Machines’

The Johnsonville aeroderivative project is the latest transformation at the 720-acre site, where the Johnsonville Fossil Plant generated power from 1951 until 2017. The site also houses gas combustion turbines built from the 1970s to around 2000.

Construction of the aeroderivative turbines began in 2022, shortly after the old coal plant was demolished.

As crews were putting the finishing touches on the project this spring, Bart Gillis reflected on his journey as electrical construction manager.

Crews followed exacting standards from start to finish – from the bottoms of the deep foundations to the tops of the 150-foot stacks, and from the units themselves to the dedicated new switchyard and control room.

“We’re very, very technically specific with how we do things,” Gillis said. “We’ve got to get it right. We can’t take shortcuts.”

Beyond all the technical precision, the turbines themselves are simply beautiful, he said.

“I just think they’re gorgeous machines,” Gillis said. “I love ‘em.”

The icing on the cake, in his view, is that everyone’s hard work helps deliver reliable, affordable power to millions of people.

“I’m very happy that I get to be a part of all this,” he said. “I’ve loved every minute of it.”

Photo Gallery

Electrical construction manager Bart Gillis surveys backup batteries in the power distribution building.