At Upgraded Gas Plant, Dedicated Crew Personifies Readiness

Readiness is like a religion for Rodney Graves’ small crew at Tennessee Valley Authority’s Kemper Combustion Turbine Plant in east-central Mississippi.

The six-person team operates “peakers,” combustion turbines that fire up quickly to meet sudden surges in power demand.

Sometimes the call comes in the middle of the night: Megawatts needed.

The crew leaps into action, bringing Kemper’s 273 megawatts onto the grid – enough to power about 160,000 homes.

“We are proud of the fact that we’ve never failed to respond,” site manager Graves said. “We’ve never had to tell them no.”

As TVA heads into summer, when hot temperatures increase power demand, Kemper is readier than ever thanks to new upgrades to enhance the reliability and capacity of its four generating units.

“We’re making investments in those machines to ensure they can provide that peak power through our peak demand periods – those cold, zero-degree days in January or the 100-degree days in August,” Eric Grau, vice president of gas operations, said.

Site foreman Tony Furline heads in from the four units at Kemper Combustion Turbine Plant in Kemper County, Mississippi.

New Control System

TVA operates simple cycle combustion turbines at nine plants in Tennessee, Alabama, Kentucky and Mississippi.

Kemper’s four units, which came online in 2002, are General Electric 7EA turbines – one of 10 different models in TVA’s combustion turbine fleet.

There are 32 active 7EA units in the fleet – the four at Kemper; 12 at Lagoon Creek Combustion Turbine Plant near Brownsville, Tennessee; four at Johnsonville Combustion Turbine Plant in Humphreys County, Tennessee; four at Gallatin Combustion Turbine Plant in Sumner County, Tennessee; and eight at Marshall Combustion Turbine Plant in Marshall County, Kentucky.

As overall demand for power rises across the Valley region, TVA can also call on these plants to provide baseload power when needed.

But their core mission? Readiness to meet peaks, night and day, 365 days a year.

While the units themselves are still running strong after more than 20 years, their control system had become outdated.

So this spring, TVA began installing a new control system on the 7EA units, starting with the ones at Kemper and Lagoon Creek. Over the next two years, TVA plans to complete the same upgrades at Johnsonville, Marshall and Gallatin, Heather Rogers, senior project manager, said.

“Control system technology has advanced considerably since the original installation of the 7EA gas turbines,” Rogers said. “By upgrading to the latest technology, these sites can more efficiently troubleshoot and proactively monitor issues to remain reliable during summer peaks.”

Furline checks on new transmitters that send data from the lube oil system to plant operators in the control room.

Upgraded Tools and Components

On a warm, late-spring day, Kemper site foreman Tony Furline pointed out some features and advantages of the brand-new upgraded controls:

- Schematics that previously could only be found in manuals

- Animations that track the unit’s startup cycles and other operations

- Easier access to replacement parts and customer support

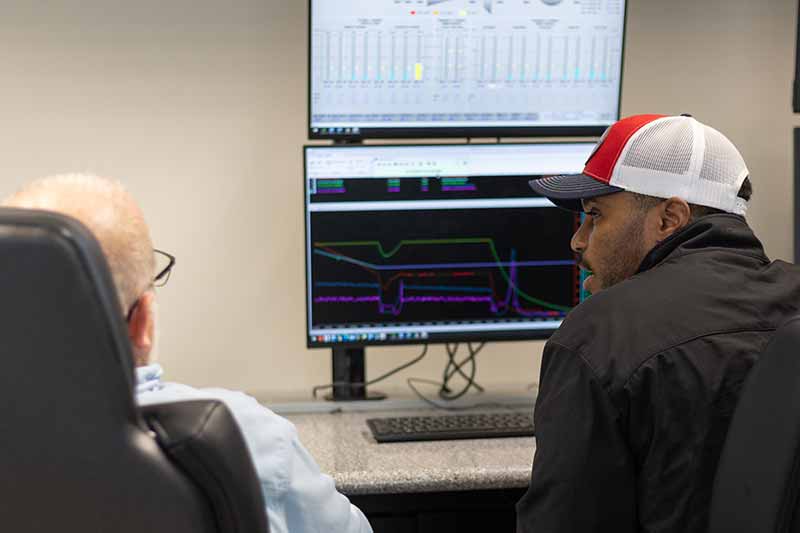

Electrical engineer Carvey Magee and mechanical engineer Ricky Cook said the new controls also feature a playback recorder and trend tracking – tools that help them do their jobs better.

Alongside the new control system, TVA added equipment around the plant itself – transmitters that allow operators to track important measurements such as lube oil pressure and tank level from the control room.

New ignition transformers and igniters – sort of like spark plugs for the units, Furline said – feature advanced diagnostics. These are also trackable from the control room, giving operators a heads-up if those components need maintenance or replacement.

Furline looks over the compressor section of one of the Kemper turbines, each of which will be able to generate an additional 5 megawatts with peak firing capacity.

Peak Firing

Another readiness upgrade at Kemper involves turning up the heat, literally, to generate more power.

It’s called peak firing mode – a higher combustion temperature that can produce approximately 5 additional megawatts per unit on the 7EA turbines.

Josh Brewer, general manager of engineering, said engineers have already tuned three 7EA units at Johnsonville to operate in peak firing mode when needed. Preliminary testing is complete at the Kemper turbines, and units at Gallatin and Lagoon Creek are next in line.

All told, engineers plan to enable peak firing at 23 7EA units this year, adding 115 megawatts to the grid.

That’s the equivalent of building one-and-a-half new 7EA turbines.

“This was the fleet with the greatest potential gain, the greatest increase for peak firing,” Brewer said of the 7EAs. “There are other peak fire-capable units outside of these 7EAs that will be worked through as well.”

The benefits of peak firing are clear, he said.

“It allows us to have more power-producing means available with existing infrastructure and equipment on the days where it’s needed most,” Brewer said. “It also helps reduce the number of new units we need to build to meet our demand.”

At Kemper’s four turbines – as with all TVA’s 7EA units – peak firing has always been an option, Graves said.

But as the region continues growing and TVA sees record-setting demand peaks, it’s vital to bring that latent capacity online so that every available megawatt is standing by.

“Reserves are extremely important to TVA,” he said. “We need to be available and ready when they need us.”

As for the people part of the equation, his team? Graves has the utmost confidence.

“These guys have never failed.”

Photo Gallery

This screen displays the lube oil system of Unit 1.

Furline closes one of the fuel gas pressure-regulating valves for the plant.

Kemper site manager Rodney Graves inspects the skid where natural gas is delivered to the plant via pipeline.

Kemper combustion turbine technician Barry Gough, at a cooling water fan with Furline (left) and Graves, has worked at the plant since it was under construction in 2002.

The operations for each of Kemper’s four units are displayed on a separate screen.

Engineers Carvey Magee, right, and Ricky Cook discuss control system upgrades.

With the new system, Furline and other operators have easy access to controller cards and data input/output cards.

This Kemper turbine shows quality check markings from its last major inspection.

PHOTO AT TOP OF PAGE: Graves operates the main fuel gas valve to Unit 1.

?