Crews Refurbish TVA’s Iconic Mountaintop Hydroelectric Plant

It’s about midafternoon on a Wednesday, deep inside the Raccoon Mountain Pumped Storage Plant.

TVA outage manager Aaron Case grins subtly as he feels a familiar rumble beneath his steel-toed boots.

Nearby, in his office, a dry erase board captures the moment: “Day 60 of 60.”

To reach this day, it had required years of planning and teamwork.

“There’s a sense of pride going into this,” Case says, absorbing it all. “It took a lot of collaboration and communication. Everybody did their part. I’m honored to be a part of this team.”

That mighty thunder underfoot? The sheer force of Raccoon Mountain sending a fresh torrent of power-generating water through heavy turbine blades and newly restored valves.

It marked the pumped storage plant’s first flow in two months, ever since a crew of 300 set out to refurbish two spherical valves on the plant’s generating units.

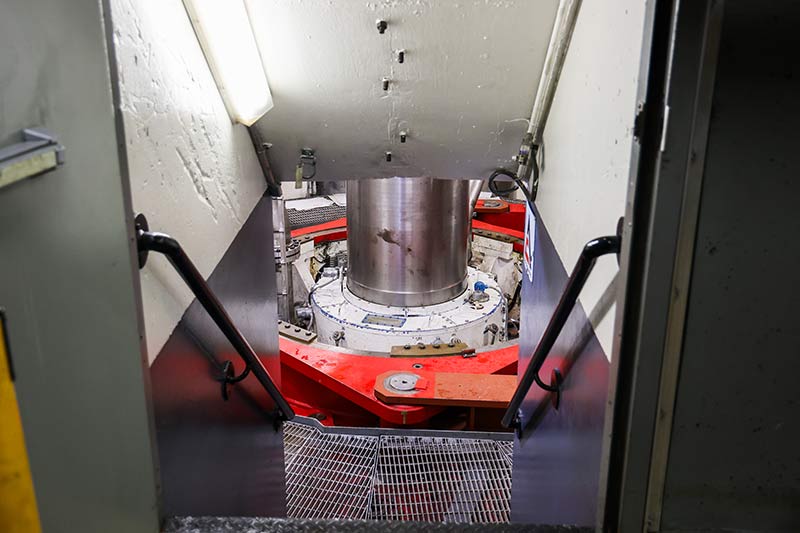

Each hydraulically operated spherical valve weighs almost 200 tons and is 10 feet in diameter. Skilled master riggers made the installation and removal of these massive valves look easy as they navigated extremely tight clearances.

Mountaintop Marvel

For Case and the many others inside TVA’s pumped storage plant, Raccoon Mountain is more than just a workplace.

It’s home.

Located just west of Chattanooga, Raccoon Mountain hosts TVA’s largest hydroelectric plant. The crown jewel of the mountaintop is its 107-billion-gallon reservoir, held behind an 8,500-foot dam.

An abundance of wildlife, nearly 30 miles of trails and a visitor center overlooking the Tennessee River Gorge also make this one of TVA’s most scenic engineering wonders.

But the true marvel is beneath the surface.

The plant is essentially a giant storage battery.

When energy demand is low, water is pumped from Nickajack Reservoir, at the base of the mountain, to the upper reservoir.

When demand is high, water is released via a tunnel in the mountain’s core to four turbines in the underground powerhouse, 1,000 feet below the upper reservoir’s surface.

Water is pumped up to the reservoir during low demand, so it can again be released to deliver more than 1,700 megawatts during peak hours.

It’s enough energy to power about 935,000 homes.

The process helps stabilize the grid by storing excess energy and producing hydroelectric power on demand, reducing stress on other energy assets.

“Having the ability to absorb power from the grid means we don’t have to cycle off other plants,” John Clapacs, TVA’s outage planning and execution manager, said.

“That means we maintain better reliability because we have less stress and strain on gas and other units. It’s a great cost-saving tool.”

These deflector cells help disperse the initial flow of water when Raccoon Mountain is in generating mode, and the enclosed structure aids in navigation protection. The platforms also serve as fishing piers.

Maintaining the Machine

Stepping into the hydroelectric plant feels almost otherworldly.

A tunnel carved directly on the mountain’s north side serves as the gateway to the power plant’s chamber. Inside, overhead lights illuminate vibrant industrial components: towering purple metal beams, bold red tubes and four massive green cylinders capped in bright yellow. They stretch across the chamber like colossal building blocks.

Each piece – down to the smallest bolt – plays a critical role in keeping the plant running smoothly.

“It’s like a submarine,” Clapacs said. “Everything has to be airtight.”

And like any finely tuned machine, regular maintenance is essential.

Much like a car needs periodic tuneups, the pumped storage facility undergoes scheduled maintenance every three, five and 10 years.

This year marked a decade-defining overhaul of the spherical valves in units 2 and 4.

“This could’ve been considered the outage of the decade,” Case said.

Maintaining components at this scale and complexity is no small task.

It involves a coordinated effort across TVA, bringing together dedicated hydro technicians, operators, laborers, hundreds of skilled craft workers, engineers, managers, safety workers, and environmental and dam safety teams to ensure the work is performed safely and on time.

When the team started planning for this maintenance event in 2023, they looked for a 60-day window where an outage of four units would have the least impact on the grid.

This careful planning enables the team to safely manage any challenges.

“Having that schedule ensured that we didn’t miss anything and that we had reliable generation down the road,” Clapacs said. “That’s how we measured success.”

Repairs and refurbishment of the spherical valves took four weeks. Crews had a dedicated spot in the plant erection bay where they could work on the units.

Skillful Execution

With the plan set, the team sprang into action on March 1.

Lifting a 200-ton valve took a day and a half.

Disassembling the spherical valves took two weeks.

Repairs and refurbishment were four weeks.

Crews safely worked around the clock, expertly handing off tasks during shift changes, ensuring they lost no momentum.

For leaders like Holli Hess, TVA’s senior manager of hydro generation, the work demanded not just technical expertise but also endurance and adaptability.

And trust.

“We understood the mission and went after it with rigor,” Hess said. “You could see the plan working, you could see the people who are well trained and well skilled executing solidly. I couldn’t be prouder of this team. Not just during lake unwatering, but every day.”

In the final two weeks, the valves were reassembled, tested and readied for operation.

On Day 60, the generators roared back to life.

When asked what he planned to do next, Case answered much as a quarterback would after winning a big game.

“I’m going to Disney World,” he said.

When the plant is operating, the turbine shaft rotates at a speed of 300 rpm. When water is admitted into the massive turbine as it’s started, it sounds like a jet engine.

‘How Can You Top That?’

Teamwork is at the core of these improvements at Raccoon Mountain.

“There wasn’t just one superhero moment,” Hess said. “It was steady increments of work that were well done. They were all well practiced, because it’s what our TVA folks do every day. They just do it consistently in the right way till the task is done – and done well.”

Now operating at full capacity, the pumped storage plant continues to deliver benefits across the Valley region.

Increased baseload generation.

Improved reliability.

Reduced strain on other power-generating assets.

And beyond power production, the surrounding greenspaces, fishing piers and trails enrich the community’s quality of life.

As TVA explores the potential construction of a pumped storage plant at either of two sites in north Alabama – or an expansion of Raccoon Mountain – these types of benefits could extend even further.

An additional pumped storage plant would enhance grid reliability with renewable energy, operating alongside new nuclear projects like small modular reactors – all designed to meet growing demand while keeping costs low.

“Who wouldn’t want another Raccoon Mountain with 30 miles of trails and recreational activities that the community embraces and enjoys?” Hess said. “What a great pairing between community benefits and reliable, clean power. How can you top that?”

PHOTO AT TOP OF PAGE: John Clapacs, outage planning and execution manager, said careful planning ensured crews at Raccoon Mountain could perform their work safely and on schedule.